Renovation Begins: Week 1

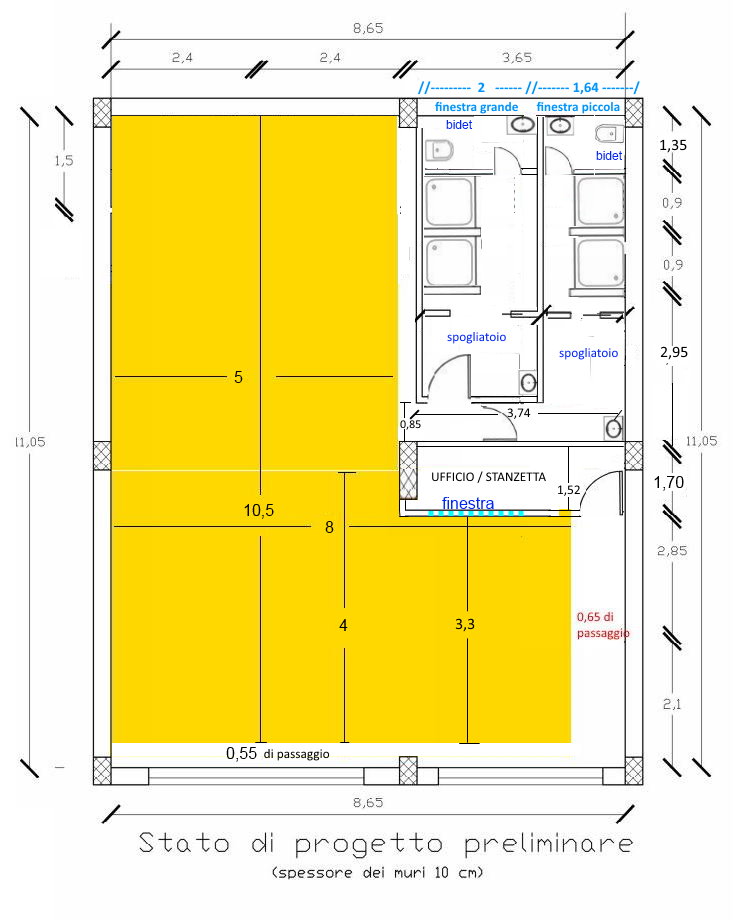

Since I have began seriously considering this commerical place, I have made few interior layout designs. As we were getting closer to starting the renovation, and after about fifteen revisions, finally we settled on this interior plan. I spent much time back and forth from the design on paper to physically set up parameters to get a feel of each space and the limitation of the place. There is nothing which can replace physically checking all the details in the room to understand what modifications need to be made.

To ensure that we get the best value given a very limited budget. I inquired from several firms. After getting several estimates from several firms, I decided on hiring a crew of mansonry, plumber/electrician, and assistant laborer at a fixed rate to keep our renovation cost to a relatively predictable and economical level while still keeping quality work. There are many things to remove, to build, including new plumbing, electrical system (to comply with current building electrical code); many materials to purchase. Here is the progress report from week one.

Part of the original interior partion was made of drywall

For building materials, trash removal has to follow strict rules. The Siporex is made of a naturally recycleable material and can be more easily disposed. Whereas drywell considered a special trash and had to be specifically disposed. Both the removal and disposal cost extra.

Not to be confused with a war zone.

Part of the original interior

partion was made of siporex, a lightweight, porous building material

With other materials, each has to be disposed accordingly, wood, plastic, cardboard, glass, each has its own procedure.

Interior cardboard doors and main wood door removed

With the original partition walls knocked down, the parameter for the new

partition walls are set

A worker using laser guidelins to mark the drywalls

To achieve fast development, we decided to skip the traditional brick laying for building the walls. Instead the mansory recomended that we use a mixture of siporex and drywall specifically designed for humid environment. As these are not weight-bearing walls, this method achieves faster speed and lower cost to realize the plan.

Change and shower rooms wall erected

By the end of week one, we can already see the partition walls of the change rooms and office. Week two will have more complex as the new plumbing and electrical system will be installed from scratch. We will have to purchase plumbing supplies, toilets, sinks, shower stalls, ceramic tiles for all wall surfaces, paint, electrical wires, outlets, switches, etc.